Case Study: Bender Donates IMI’s for Students Racing in Hyperloop

In 2013, Elon Musk published a white paper on his idea of a new method of high-speed ground transportation, called Hyperloop. SpaceX, founded by Musk, announced the Hyperloop Pod competition in 2015 to encourage students to develop a functional prototype. The competition was first held in 2017 and has been held each year subsequently. The competition has been judged solely on one criterion: the pods reach maximum speed with successful deceleration. The ultimate goal of this competition and the Hyperloop is to eventually achieve a new means of transportation via a tube system, where people will be propelled at airplane-comparable speeds between cities, at a fraction of current cost, and in an environmentally safe and economical manner.

Designing the Pod

The technical hurdles are immense with this competition. There are ample things to consider since the tube contains a vacuum to reduce air resistance for the pods. Many of the test pods are currently self-propelled, and this year, they will have to go much farther than in previous years – 6.2 miles instead of 1 km.

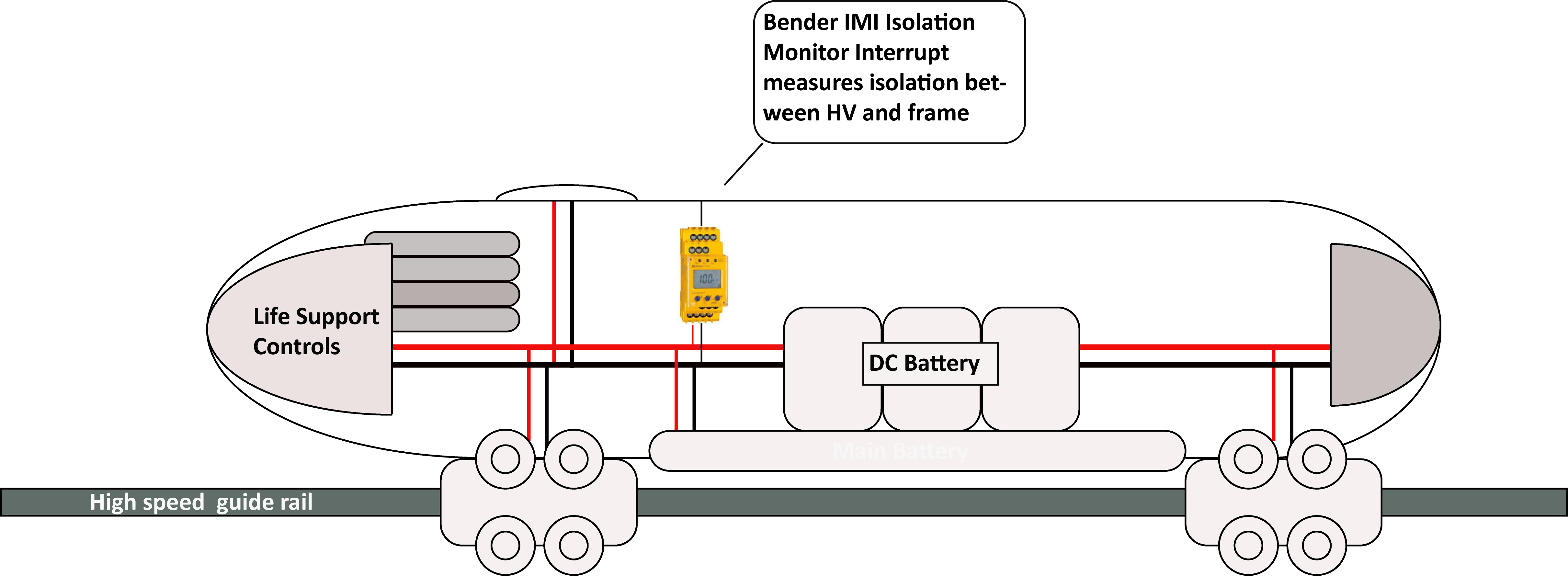

When designing for the competition, two teams decided that the electrical system on board the pods should be ungrounded, similar to the systems found onboard of conventional electric vehicles.

Bender donates IR155 IMI for students

Bender supplied an IR155 IMI (isolation monitor interrupter) board to the teams to guarantee the electrical safety and proper operation of the pod. Here, the IR155 will be connected to the Pod’s battery, and constantly monitor its level of isolation towards the frame. Any breakdown will be recognized immediately and alert the team of the need to fix and repair. The IR155 is the best suited IMI for this task because of its small footprint and active measuring capabilities. The latter enables the IMI to measure the Pod’s electrical integrity versus the frame before and during operation. This sets it apart from passive measuring devices such as H-bridges, which can only operate when the Pod is energized.

The importance of high quality equipment in the pods

Accurate information on potential electrical shorts is vital for sustaining the pod and its potential future passengers during the operation. Bender devices are superior to other existing technologies due to their accuracy in measuring resistance during all kinds of situations and circuits. The Bender IMI will monitor isolation from the battery, through inverters, converters all the way into the drive train under all load and temperature conditions.

Continuous uptime and the utmost degree of electrical safety is a must have for the future of fast speed travel. Bender IMIs are here to provide the reliability needed to make this type of future travel a reality.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.

.jpg)

.jpg?width=352&name=Blank%20300%20x%20175%20(21).jpg)

.jpg?width=352&name=Blank%20300%20x%20175%20(5).jpg)

.jpg?width=352&name=Blank%20300%20x%20175%20(14).jpg)