Generators — Solutions for Reliable and Consistent Power

Few people would dispute the fact that generators are extremely useful appliances. They supply electrical power during a power outage and prevent discontinuity of daily activities or disruption of business operations. Generators work by converting mechanical energy into electricity when local power grids are down or inaccessible.

One type of generator is called a cogeneration generator, or combined heat and power (CHP), where the production of electricity or mechanical power and thermal energy (heat and or cooling) from a single source of energy occurs simultaneously. Another similar and newer application generators are used for is called "peak shaving". This is the process of reducing the amount of energy purchased from utility companies during peak demand. This technique is used during times when electricity rates are more expensive than what it costs to operate single or multiple generators, so the generator kicks in instead of the main power source, even though it is still operational at that time.

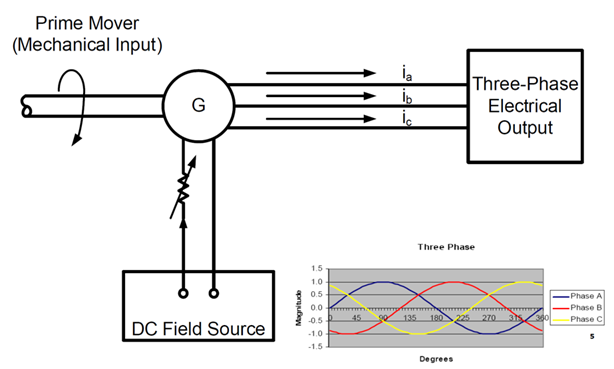

An AC three-phase generator hosts two winding configuration types — a wye configuration, which can be solid or resistance grounded, and a delta configuration, which is ungrounded. These connection types are named after the Greek and English letter that each resembles. Since the generator function is there to provide an uninterruptible power supply, its reliability and health are crucial. It is essential that the prime mover (as shown in image 1) is maintained to move or turn the generator to produce electrical energy.

All electrical systems can experience electrical faults and abnormal electrical conditions. A large majority of electrical faults start as phase-to-ground faults, and if left undetected, can cause damage and interruption to the power supply. Generators of all kinds are not immune to these electrical faults, and therefore, early detection and accurate monitoring can mitigate damage to the generator and extend its lifecycle.

Abnormal electrical conditions may be caused by the generator or by the system, so it is critical that they be protected from both external and internal faults. This can be done with protection relays based on the size of the generator, from 12kW to 2MW+. We need to take the same approach we use for system grounding on electrical systems that are supplied by the utility with generators to mitigate this type of damage. Since the goal is to limit surge voltages and current in the windings caused by transient overvoltage, the impedance grounding of the generator neutral or X0 can both protect the windings and potentially save the generator from catastrophic damages.

Utilizing high resistance grounding (HRG) where a neutral grounding resistor (NGR) is connected from the generator transformer to ground can limit the fault current during a phase-to-ground fault. Typically, the NGR will limit the fault current to 5 or 10 A with the following benefits:

- Reduces arc flash hazards associated with phase-to-ground faults

- Eliminates damage to rotator and stator

- Prevents operation of over current devices until fault can be located

- Can be used alongside ground fault location system

- Can be used on low- or medium-voltage systems

For generators with a delta winding, Bender also offers insulation monitoring devices for ungrounded applications. It is a general promise of generator suppliers to deliver reliable and consistent power to their customers. To meet this goal, it is crucial to have a reliable and healthy system.

Bender offers services for consultants for NGR sizing and charging current calculations, to propose the right solution for ground fault and NGR monitoring. No matter what kind of grounding arrangement, Bender provides a solution.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.

-1.jpg?width=352&name=Blank%20300%20x%20175%20(15)-1.jpg)