Case Study: Komatsu Integrates Bender Ground-Fault Solutions for New Manufacturing Facility

Komatsu's Problem

Komatsu Limited has been a powerhouse in manufacturing equipment for construction, mining, the military, and industrial applications for over 100 years. Earlier this year, an operator at Komatsu requested support for a future facility they were building. He knew he wanted to have a quality solution to serve Komatsu for the installation's life. Experiences showed that ground faults lead to costly, unplanned interruptions and put a heavy load on maintenance resources, which he wanted to avoid. Initial discussions eventually led to additional webinars with consulting engineers and equipment manufacturers, and they decided to put their trust in Bender.

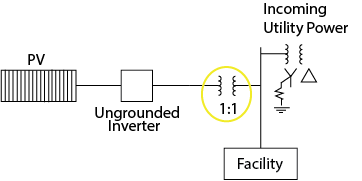

Like many modern systems, the supply of power to the facility included a renewable energy source. At this point, the PV equipment provider stated their system was not compatible with high resistance grounding (HRG). This hurdle for HRG was quickly overcome by installing an isolation transformer between the bus and PV inverter.

Bender's Solution

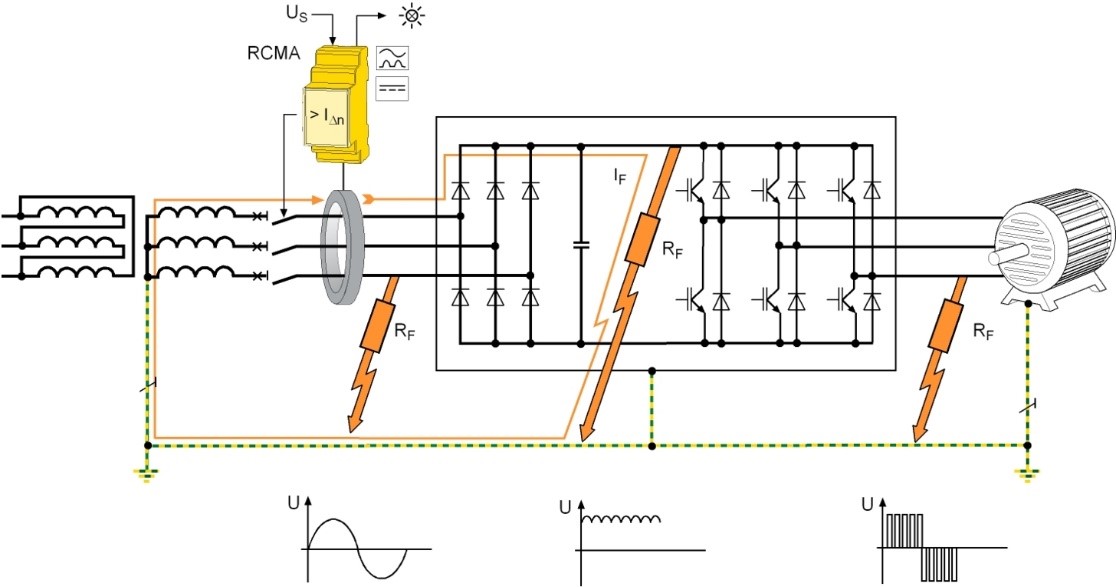

Bender provides products compatible with ungrounded, solidly grounded, low resistance grounded (LRG), and high resistance grounded (HRG) power supplies. In modern applications, it is prevalent to see a mixture of different methods on the same drawing. For example, medium voltage adjustable speed drives are a popular component consisting of grounded and ungrounded sections.

Bender’s 75 years of experience has allowed the development of products that meet the demands of adjustable speed drives and other nonlinear loads. Tailoring the solution for Komatsu’s manufacturing plant needs was possible with the RCMS490, 12 channel ground-fault location relay. Each of its 12 channels can accept different current sensors with the appropriate frequency response for the load.

Examining the fault characteristics in Figure 2 (below) can show fault waveforms that will appear with different fault locations. The CTUB-100 series of current sensors allows fault detection regardless of the fault’s fundamental frequency. For enhanced preventative maintenance, ground leakage current trends are also possible for accurate measurement from DC up to 400 Hz. The wide frequency response range provides unparalleled protection to nonlinear loads.

The Problem with Ground Faults

Ground faults account for approximately 90% of electrical faults in a system. It is understandable as insulation break down for any reason would typically lead to a conductor contacting metal and making a single-phase-to-ground fault (ground fault). Although it is easy to think, “Ground faults likely won’t occur at my facility,” it is still essential to plan for them accordingly. Samuel Beans, a facilities engineer at Komatsu, stated, “The HRG system prevented any major problems from occurring when the ground cable insulation melted and contacted a phase.” Komatsu has successfully identified and located six ground faults within this year on their installation. Without the implemented Bender protection, these events could have led to equipment damage, fires, and/or injured personnel.

They say things are bigger in Texas. That is reinforced when you look at the size of the equipment being built at Komatsu’s campus-style facility in Longview, TX. Simply walking from one building to another can be a time-consuming adventure. The Bender HRG Series 2 solution provided a remote diagnostic tool to help automatically locate faults even when not on site. While leaving a power system running with a single ground fault is an advantage of HRG systems – not clearing the faults in a short period leaves a system prone to phase-to-phase faults. Bender solutions help save time and money and better protect critical manufacturing.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.

.jpg?width=352&name=Ships%20%26%20Vessels%20300x175%20copy%20copy%20(1).jpg)