Ground Fault Protection in Oil and Gas Facilities

In the high-stakes world of oil and gas operations, electrical reliability and safety are paramount. Any disruption in the power supply can result in substantial downtime and compromised safety. One critical aspect of maintaining electrical reliability while ensuring the safety of personnel and assets is ground fault protection. In this article, we will explore the significance of ground fault protection in oil and gas facilities, how it can prevent downtime, and why electrical engineers play a pivotal role in achieving these objectives.

Understanding ground faults

Before delving into ground fault protection, it's essential to comprehend what ground faults are and their potential consequences. A ground fault is an unintentional electrical connection between a live electrical conductor and the earth, typically due to insulation breakdown or equipment failure. When a ground fault occurs, it can lead to equipment damage, power interruptions, and, most alarmingly, electrical shock hazards. For oil and gas facilities, any of these consequences can be disastrous.

Preventative maintenance and ground fault protection

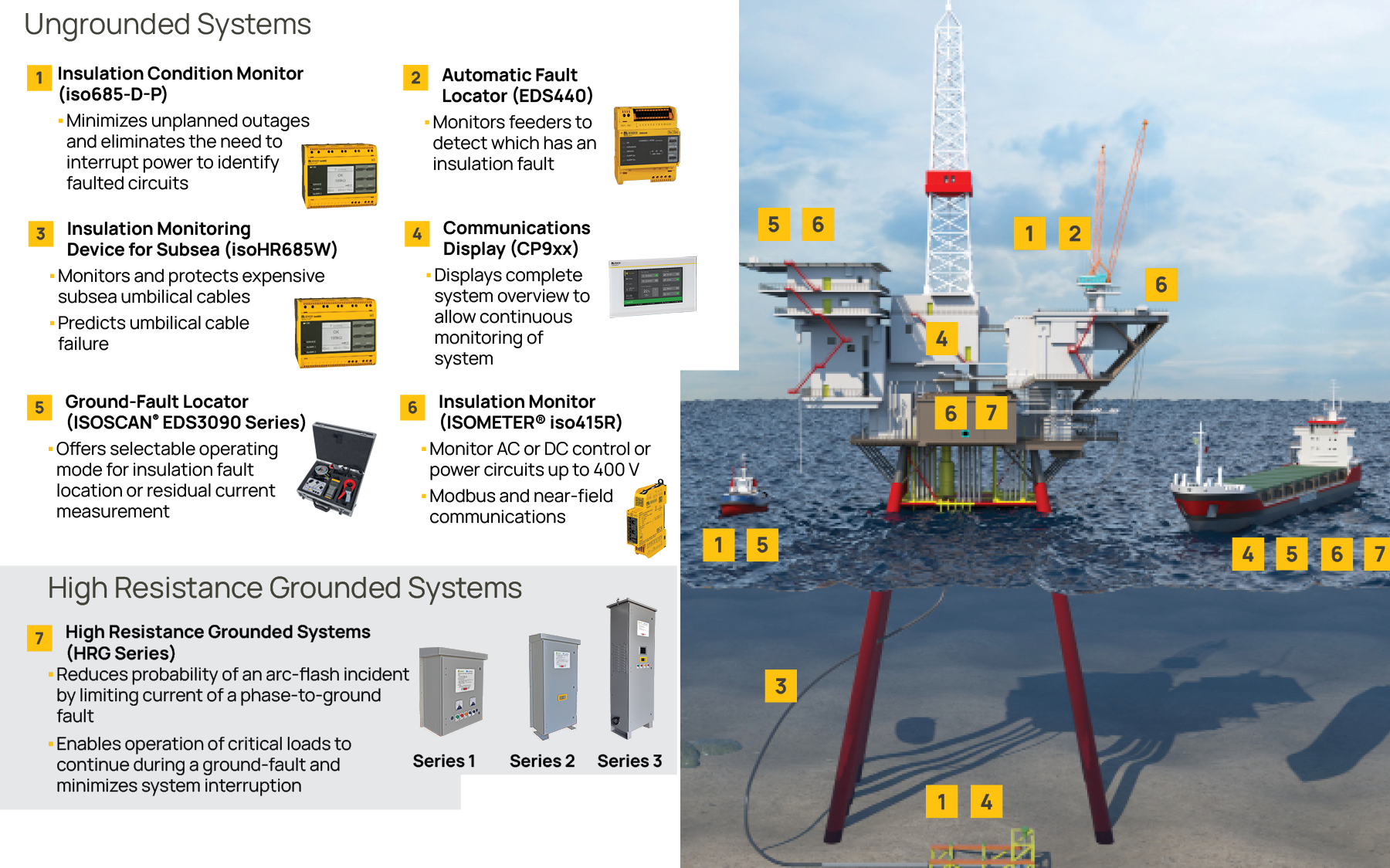

Preventative maintenance is the first line of defense against ground faults in oil and gas facilities. Regular inspections and testing of electrical systems can identify potential issues before they escalate into critical problems. This is where ground fault protection systems, such as those provided by companies like Bender, come into play. Bender provides 24/7 monitoring of the electrical system and can offer solutions for both online and offline systems. This can also help reduce how often these systems need to be taken offline for testing.

Bender ground fault protection solutions are designed to detect and respond to ground faults swiftly and indicate failures as early as possible. These systems continuously monitor the electrical network for any low levels of ground faults or insulation failures and provide the ability to alarm and trend this data. This allows for oil and gas facilities to better understand ground faults in early development in the facility and schedule maintenance versus waiting until a serious ground fault results in unexpected shutdown. When a critical ground fault is detected, the system can be designed to isolate the faulty circuit/feeder, minimizing the potential damage.

Oil and gas facilities may experience issues with ground fault equipment failing to detect both AC and DC ground faults. The typical ground fault relays only detect an AC ground fault at the fundamental frequency. DC ground faults and low-frequency AC ground faults flow through the system undetected and continue to get larger and eventually damage equipment, specifically the variable frequency drives (VFDs). Bender technology provides the capability to detect both AC and DC ground faults, ensuring no ground faults go undetected and are easier to troubleshoot in the event that they do occur. Pinpointing ground faults before they lead to catastrophic failures is crucial for maintaining electrical reliability in these critical operations.

These protection relays in a small form factor are combined with AC/DC CTs to protect all the large drives in the plant and detect any DC faults at 0Hz and low-frequency AC faults occurring inside and after the VFD. The end user needs to detect AC and DC faults early to avoid damage to the drive in their plants that only have rudimentary ground fault protection. This will result in the reduction of operational costs and avoid unexpected downtime when having to service these drives in the plants.

Reducing downtime

Downtime is the enemy of productivity and profitability in the oil and gas industry. A single unplanned shutdown can result in significant financial losses, not to mention the potential safety risks. Ground fault protection systems are a vital component of reducing downtime. By detecting and isolating ground faults promptly, these systems prevent minor issues from escalating into major problems.

In the event of a ground fault, the system can trip the circuit breaker, disconnecting the faulty part of the system while allowing the unaffected portions to continue functioning. This minimizes downtime, allowing operations to resume as quickly as possible. In a sector where every minute counts, the role of ground fault protection and monitoring in keeping the lights on and the machines running cannot be overstated.

Electrical engineers in the oil and gas industry

The effectiveness of ground fault protection systems depends on the expertise of electrical engineers working in the oil and gas industry. These professionals are responsible for designing, implementing, and maintaining electrical systems in these facilities. They play a crucial role in ensuring that ground fault protection is not just a concept but a practical and effective solution.

Electrical engineers are the bridge between theory and application. They need to understand the specific needs and challenges of oil and gas facilities, integrating ground fault protection into the overall electrical infrastructure. This involves selecting the right equipment, designing circuitry, and ensuring compliance with safety standards. The expertise Bender has working on ground fault systems and design with electrical engineers and end users ensures that ground fault protection is seamlessly integrated into the facility's operations.

Explore Bender solutions

Revisit our oil & gas solutions webinar

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.

.jpg?width=352&name=Blank%20300%20x%20175%20(2).jpg)