Case Study: Enhancing Safety in Battery Energy Storage Systems (BESS) with Ground Fault Detection

Battery Energy Storage Systems (BESS) play a vital role in modernizing energy grids and supporting the integration of renewable energy. However, ensuring the safety of BESS installations is paramount due to the potential risks associated with ground faults. This case study explores the implementation of Bender's ground fault detection technology in a BESS installation, highlighting its effectiveness in preventing electrical hazards and ensuring reliable operation. Ground fault detection systems are crucial for identifying and mitigating electrical hazards promptly.

Case Study Overview

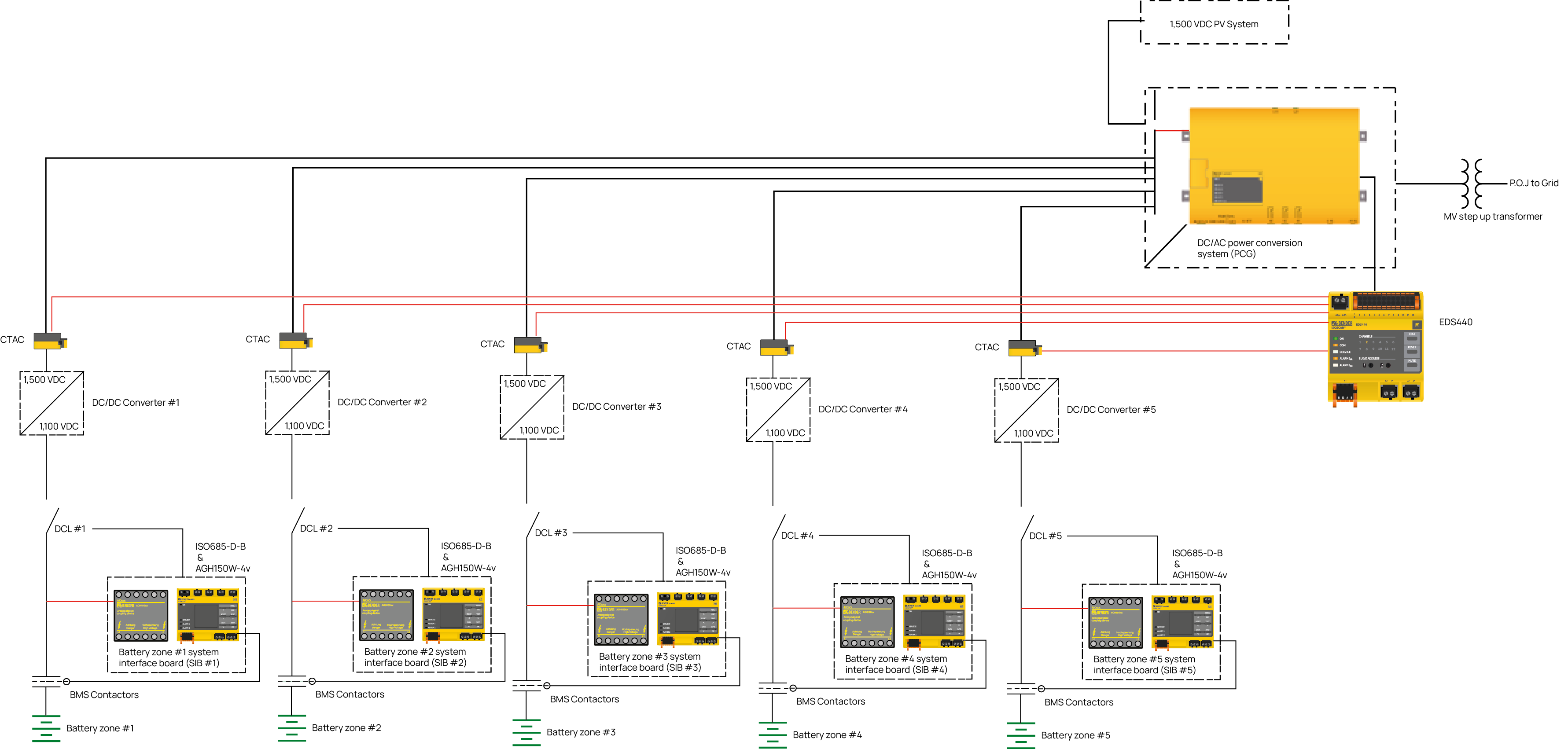

In this scenario, the customer was seeking to integrate a solar farm with the local electrical grid. This case study considers a medium-scale BESS installation with a capacity of 5 MW/10 MWh. The BESS comprises lithium-ion batteries, inverters, transformers, and associated control systems. To ensure the safety of personnel, equipment, and the grid, a Bender ground fault detection system was integrated into the BESS setup.

Ground Fault Detection Solution

Bender's ground fault detection system is designed to identify and locate ground faults in electrical systems, minimizing the risk of electrical shock, fire, and system downtime. The system employs advanced insulation monitoring techniques to continuously monitor the electrical integrity of the installation, providing real-time alerts and data for maintenance teams to take appropriate actions swiftly.

The ground fault detection system is strategically installed at key points within the BESS infrastructure:

- At the main connection point between the solar farm, BESS, and the grid.

- Along the DC/DC converters.

- At the battery bank

- The PV side of the system while it is being monitored, ground fault location has not been implemented.

Having multiple insulation monitors serves many purposes. The iso1685 series with pulsing pairs to the EDS440 series. The iso1685 is the main device that will be monitoring the entire system (BESS and PV). Once the device detects a low insulation resistance value, it will switch into a pulsing mode. The unit will work together with the EDS440 and the connected CT (current transformers), to locate the faulted battery bank. Once the fault is detected, the operator can isolate the faulted bank once it is appropriate to do so.

The purpose of the additional insulation monitors at each battery bank, is to provide constant monitoring for the isolated bank. These units all are in a stand-by state while the banks are connected to the rest of the system and they come into function only when the DC switch is opened. The purpose of the iso685-D-B with AGH150W-4, is to provide continuous monitoring of the faulted battery bank insulation during repair or maintenance. This approach allows for the operators to clearly know when the faulted battery has been properly repaired and it is good to bring back online.

The system continuously measures the insulation resistance and identifies any potential ground faults that could compromise the safety of the installation.

Results and Benefits

The implementation of Bender's ground fault detection system yields several significant benefits:

Enhanced safety: The system promptly detects ground faults and triggers alarms, allowing operators to isolate faulty sections before hazards escalate.

Reduced downtime: Swift fault detection minimizes downtime by facilitating rapid maintenance and repairs.

Data-driven insights: The system records historical data on insulation resistance, helping maintenance teams analyze trends and implement proactive measures.

Compliance: The installation meets safety standards and regulations, ensuring the protection of workers and compliance with industry requirements.

Conclusion

The integration of Bender's ground fault detection system in the BESS installation underscores the critical role of advanced safety technologies in modern energy systems. By providing real-time monitoring and early fault detection, the system ensures the safety of personnel, assets, and the electrical grid. This case study highlights the importance of proactive safety measures in enabling the reliable and sustainable operation of battery energy storage systems.

As technology continues to evolve, future considerations might involve the integration of AI and machine learning algorithms to predict potential ground faults based on historical data. This has the potential to further enhance the safety and reliability of BESS installations while optimizing maintenance efforts.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.