Electrical Safety in Low Resistance Grounded Systems

Do you know that low resistance grounding (LRG) systems can be an excellent option to improve electrical safety in mining, oil & gas, utilities, and other industrial facilities?

It is common to have questions from end users, electric designers, and technical personnel regarding which grounding system should be used in an electrical facility, whether new construction or even if it is already operating; in either case, partners are open to migrating from the current grounding system. This predisposition to change is due to the continuous search to improve operations for personnel and the facility and to guarantee the continuity of the power supply.

For this reason, to choose a grounding system, it is essential to consider factors such as the criticality of the application, current-voltage levels, power supply, system charging current level, and maintained cost, among others, because the protection and the electrical insulation monitoring system are designed depending on the grounding system.

Each System has advantages and disadvantages

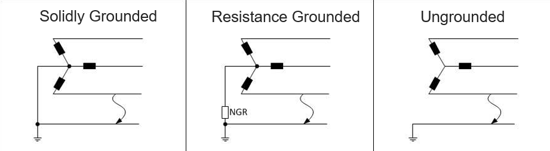

It is necessary to highlight that there is no good or bad grounding system, and it is critical to understand the system and the operation's needs. Therefore, looking at the different grounding systems and exploring their advantages and disadvantages is essential. Grounding systems commonly used are solidly grounded, ungrounded, and resistance grounded (NGR), which it is divided into two categories, high resistance grounding (HRG) and low resistance grounding (LRG).

The LRG system has the advantage of limiting the fault current to a known value, with 100 – 400 A being typical. The resistor is calculated applying Ohms Law Rngr=Vln/Ig, where Vln is the system line to neutral voltage and Ig is the desired let-through current. The higher currents allowed in the LRG system compared to HRG give the protection adequate current to operate. A ground fault is detected by protection relays and cleared by breakers or contactors. There is adequate current for older non-sensitive protection devices to operate.

Examples of applications of these LGR grounding systems can be found in large rotating machinery, Medium voltage mobile mining equipment, and transformers for primary and secondary distribution where there may be high levels of charging current, usually in medium voltage voltages applications.

Low resistance ground system monitoring: NGRM750 and NGRM550

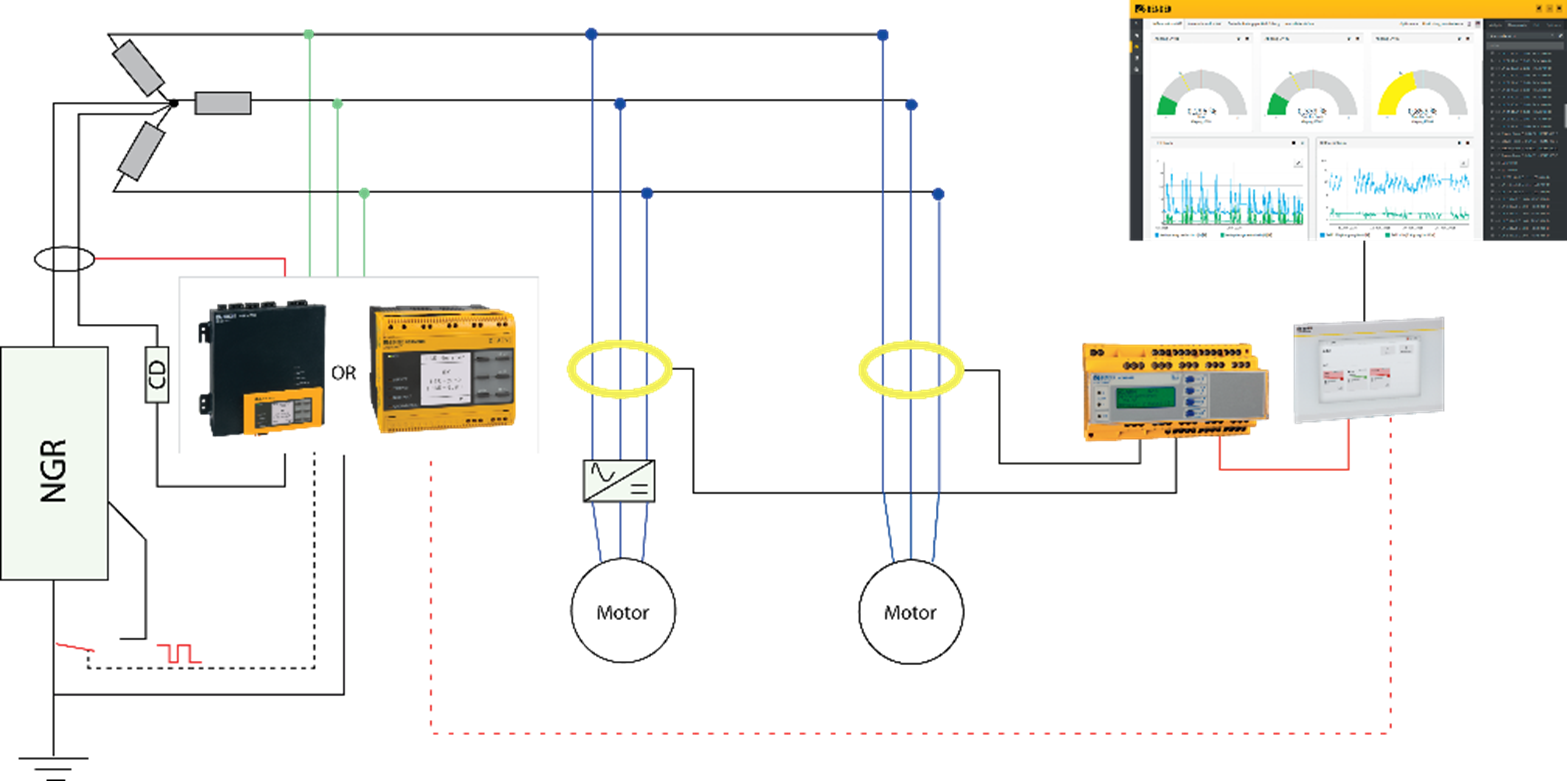

Like most grounded systems, ground-fault protection is provided by current detection. There must be a return path to the source to allow current flow. To guarantee that ground-fault protection can operate and provide the desired electrical safety in an LRG system, it is necessary to ensure the integrity of the resistance and detect lower current ground faults. This is achieved through the Bender NGRM750 and NGMR550 monitors, which provide information on resistance measurement, early ground-fault detection, integrated web server communication, voltage monitoring, operation up to 5000 m.a.s.l (16,404 ft.), and other advantages for a wide range of operation conditions.

Resistance and NGR monitor integrated system

Bender has developed integrated solutions that include the resistor and monitor and can be customized to meet the customer’s needs and their unique application. Many customers find it useful to add more sensitive ground-fault protection downstream from the NGRM to allow selective coordination, whereby only the faulted circuit is de-energized. The RCMS device in the image below is one relay that can provide protection for up to 12 circuits or loads.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.

.jpg?width=352&name=Blank%20300%20x%20175%20(8).jpg)

.jpg?width=352&name=Blank%20300%20x%20175%20(10).jpg)